Why Are Instruments Gauges Essential for Accurate Measurements?

Accurate measurements are vital in various industries. Instruments gauges play a crucial role in achieving this accuracy. These tools help ensure that data collected is reliable. They measure temperature, pressure, and other variables in real-time.

Without instruments gauges, errors can lead to serious consequences. For instance, a slight deviation in pressure measurements can cause a machinery failure. These gauges require regular calibration to maintain their effectiveness. However, some users might neglect this, resulting in inaccurate readings.

It's essential to recognize the limitations of instruments gauges. Not all gauges are suited for every environment. Some may struggle under extreme conditions, affecting performance. Therefore, understanding their capabilities is equally important. Proper selection and maintenance of instruments gauges can dramatically improve precision in measurements.

Importance of Instrument Gauges in Measurement Accuracy

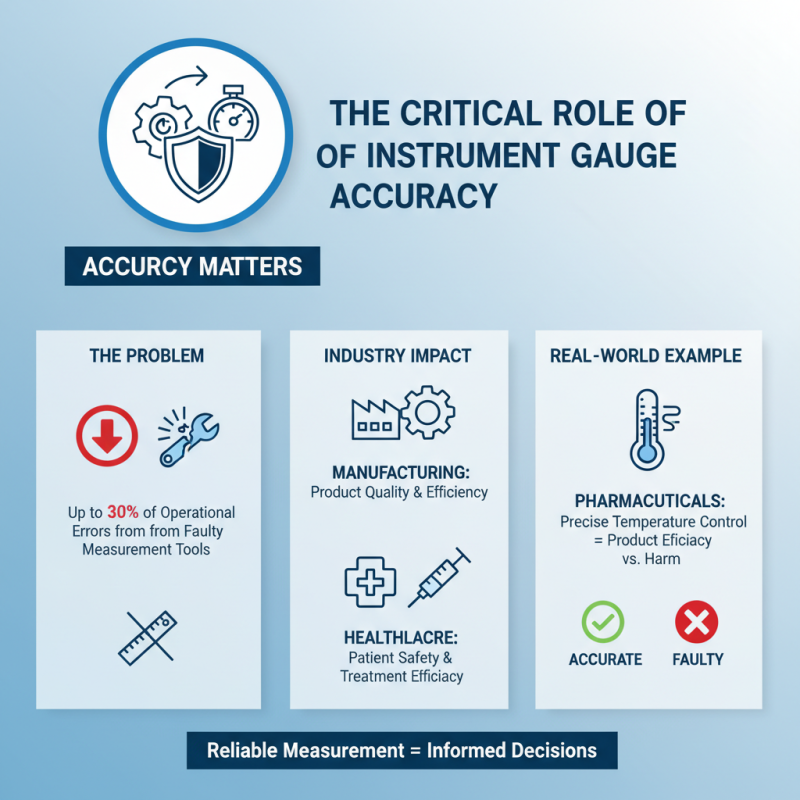

Instrument gauges play a critical role in ensuring measurement accuracy across various industries. According to recent studies, up to 30% of operational errors can stem from faulty measurement tools. Accuracy is paramount, especially in manufacturing and healthcare. For example, precise temperature readings in pharmaceuticals can be the difference between product efficacy and potential harm.

In construction, incorrect measurements can lead to significant financial losses. The National Institute of Standards and Technology reports that even a 1% error in measurements can result in a 2% increase in costs. Accurate readings help avoid rework and ensure safety. This stresses the need for reliable instrument gauges. However, many industries still rely on outdated equipment, which can compromise precision.

Additionally, training personnel on the correct use of these instruments is often overlooked. Many technicians may misinterpret gauge readings due to a lack of training. This can lead to further inaccuracies. Companies must invest in both advanced instruments and proper training to achieve the best results. Recognizing these shortcomings is vital for improvement.

Types of Instrument Gauges Used in Various Industries

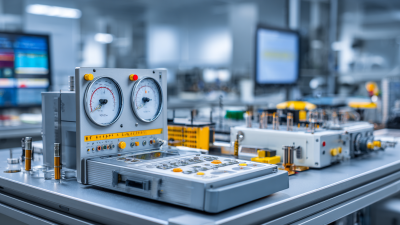

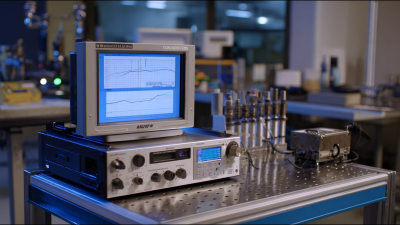

Instrument gauges play a vital role across various industries. They provide precise measurements that ensure safety and efficiency. In manufacturing, pressure gauges monitor steam systems. They prevent equipment failures and enhance productivity. These devices also indicate trends that help in maintaining optimal performance levels.

In the automotive sector, tachometers measure engine speed. Mechanics rely on accurate readings to tune engines properly. In healthcare, vital sign monitors track patients' conditions. Nurses depend on these gauges to make quick decisions. However, these tools can sometimes offer misleading data if not calibrated regularly.

There are also challenges in interpreting gauge readings. Variations in temperature can affect accuracy. Environmental factors can lead to unexpected fluctuations. Regular maintenance is necessary to ensure reliability. It's crucial to train personnel in gauge operation for better outcomes. Understanding these nuances can improve overall measurement effectiveness.

Why Are Instruments Gauges Essential for Accurate Measurements? - Types of Instrument Gauges Used in Various Industries

| Gauge Type | Measurement Range | Industry Usage | Accuracy |

|---|---|---|---|

| Pressure Gauge | 0-300 psi | Oil & Gas | ±1% FS |

| Temperature Gauge | -50 to 500 °C | Manufacturing | ±0.5% FS |

| Flow Meter | 0.1 to 100 L/min | Water Treatment | ±2% FS |

| Voltage Meter | 0-600 V | Electrical | ±1% FS |

| pH Meter | 0 to 14 pH | Food & Beverage | ±0.1 pH |

How Calibration Enhances the Precision of Instrument Gauges

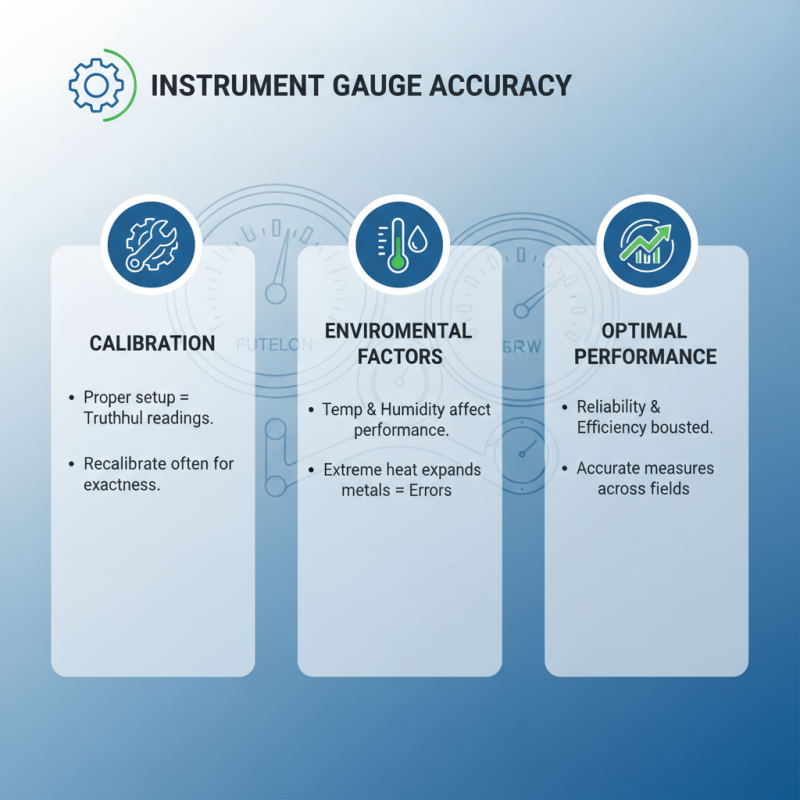

Calibration is crucial for instrument gauges. It ensures that measurements are both accurate and reliable. Without proper calibration, instruments can give false readings. This can lead to significant errors in various industries. A simple miscalculation can result in costly mistakes. Calibration helps identify these potential issues before they escalate.

The process of calibration involves comparing an instrument's output with a known standard. This usually includes adjustments to align the readings. Regular calibration allows for consistent performance. It also helps maintain confidence in the instruments being used. However, it's easy to overlook this step. Relying on outdated data can be dangerous.

Instruments should be calibrated under controlled conditions. Environmental factors can affect these readings. Temperature, humidity, and pressure all play a role. If these variables are not monitored, results may vary widely. It's vital to address these challenges to achieve optimal performance. Calibration is not a one-time task; it requires ongoing attention.

Factors Influencing the Performance of Instrument Gauges

Instrument gauges play a vital role in achieving accurate measurements across various fields. Several factors influence their performance, impacting their reliability and efficiency. Accuracy hinges on proper calibration. If gauges are not calibrated correctly, the readings can be misleading. Regular recalibration is essential to ensure precision. Environmental conditions also matter. Temperature and humidity can affect the functioning of gauges. For instance, extreme heat may cause metal components to expand, leading to erroneous measurements.

Another critical aspect is the gauge's design. Simple designs can be more effective in some situations. Sometimes, complex features create confusion. The user should understand how to read the gauge properly. Misinterpretation of readings is common among inexperienced users. Therefore, training is crucial.

Material quality is yet another determinant. Gauges made from subpar materials may degrade quickly. This can lead to inaccuracies over time. Additionally, maintenance is necessary. Ignoring maintenance can compromise performance. It's essential to regularly check for wear and tear. In some cases, a replacement may become inevitable. Taking these factors into account helps ensure that instrument gauges serve their purpose effectively.

Common Applications of Instrument Gauges in Daily Operations

Instrument gauges play a vital role in many daily operations, ensuring accuracy in various measurements. In manufacturing environments, these gauges monitor pressure, temperature, and flow rates. A small error in these measurements can lead to production issues. Workers rely on these gauges to maintain optimal conditions, preventing waste and ensuring quality.

In the automotive industry, instrument gauges help monitor engine performance and fuel efficiency. Mechanics use these tools to identify potential issues before they escalate. Regular checks can save money and reduce downtime. However, sometimes operators overlook irregular readings, which can lead to more significant problems.

In healthcare, instrument gauges measure vital signs. Equipment displays blood pressure and heart rates. Accurate readings are crucial for patient care. Yet, staff may misinterpret these readings due to distractions or equipment malfunctions. Recognizing these pitfalls can lead to improved practices and better outcomes. Being aware of the limitations of these tools is essential for all fields.

Related Posts

-

10 Essential Tips for Choosing the Right Test Instruments for Your Business

-

Unlocking the Advantages of Advanced Test Instruments for Quality Assurance

-

7 Reasons Why Investing in Test Instruments Can Transform Your Quality Assurance Process

-

Ultimate Guide to Understanding Measuring Instruments for Your Business Success

-

What is the Role of Test Instruments in Ensuring Quality and Safety Standards

-

Top 5 Essential Test Instruments for Accurate Measurements in Your Projects

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments