5 Essential Tips for Choosing the Right Liquid Filled Gauges

In the realm of pressure measurement, liquid filled gauges have emerged as a preferred choice across various industries owing to their ability to withstand harsh environments and provide accurate readings. According to a recent market research report, the global liquid filled gauges market is projected to grow at a CAGR of 5.4% from 2022 to 2030, underscoring the increasing demand for reliable pressure measurement solutions. Industries such as oil and gas, chemical processing, and water treatment are particularly reliant on these gauges due to their performance in mitigating vibration effects and protecting the internal mechanism from corrosive materials. With the market's growth and the critical role these instruments play in operational safety and efficiency, it becomes imperative for professionals to understand how to select the most appropriate liquid filled gauges for their specific applications. In this blog, we will explore five essential tips that will guide you in making an informed choice when selecting liquid filled gauges for your operational needs.

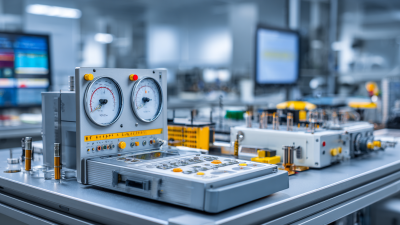

Key Considerations for Selecting Liquid Filled Gauges: Accuracy and Range Testing

When selecting liquid filled gauges, accuracy and range testing are paramount considerations. According to a recent report by the American Society of Mechanical Engineers (ASME), approximately 80% of measurement errors in mechanical systems can be traced back to improper gauge selection. Ensuring that the gauge can operate effectively within the specified range is crucial; this is where liquid filling comes into play. Liquid-filled gauges are designed not only to dampen vibrations but also to provide enhanced stability, making them ideal for fluctuating environments.

One essential tip for choosing the right liquid filled gauge is to evaluate the expected temperature and pressure range. For instance, gauges used in high-pressure applications, particularly in oil and gas industries, require precision that can be compromised if the gauge is not rated for the specific conditions. It's advisable to select gauges that have a range exceeding the maximum expected pressure by at least 1.5 times to prevent inaccuracies and potential failures.

Additionally, consider the method of accuracy verification. According to a survey conducted by the International Society of Automation, more than 65% of users reported that regular calibration and testing significantly improved their systems' operational efficiency. Users should opt for gauges that offer features such as replaceable internals or recalibration options to maintain accuracy over time. This ensures reliability in performance, providing peace of mind in critical applications.

Understanding the Impact of Viscosity on Liquid Filled Gauge Performance

When selecting the appropriate liquid-filled gauge, understanding the impact of viscosity is crucial for optimal performance. Viscosity, the measure of a fluid's resistance to flow, can significantly influence the responsiveness and accuracy of pressure readings. Research indicates that fluids with higher viscosity tend to dampen the gauge’s response time, potentially leading to delayed readings in rapidly changing pressure environments. For instance, a study published by the American Society of Mechanical Engineers highlighted that gauges filled with silicone oil, known for its lower viscosity, provided more accurate readings under dynamic pressure conditions compared to those filled with glycerin, which has a higher viscosity.

Moreover, the choice of filling fluid can also affect the gauge's performance in extreme temperatures. According to a report from the International Society of Automation, silicone-based fluids maintain their viscosity better than their glycerin counterparts when exposed to high temperatures, thus ensuring consistent operation. In applications involving high-temperature fluctuations, selecting a gauge with a suitable liquid filling can prevent issues such as lag in response or false readings, ultimately enhancing the reliability of measurement in critical industrial processes. These considerations highlight the importance of evaluating viscosity alongside other factors when choosing liquid-filled gauges to ensure accurate and timely performance.

5 Essential Tips for Choosing the Right Liquid Filled Gauges

Material Selection for Liquid Filled Gauges: Compatibility and Durability Factors

When selecting liquid-filled gauges, material compatibility and durability are paramount factors to consider. The liquid filling not only serves to dampen vibrations and provide better readability, but it also interacts with the materials of the gauge housing. Common materials for liquid-filled gauges include stainless steel, plastic, and bronze. Each material offers distinct advantages based on the environment in which the gauge will operate. For example, stainless steel is ideal for corrosive environments due to its superior resistance to oxidation, while plastic may be suitable for less demanding applications that avoid exposure to harsh chemicals.

Moreover, the choice of filling liquid itself can influence the longevity and reliability of the gauge. Common options include glycerin, silicone, and various oils, each presenting different levels of temperature resistance and compatibility with specific environments. It’s essential to align the filling liquid with the gauge materials to prevent degradation over time. Additionally, considering factors such as temperature fluctuations and the presence of contaminants can greatly impact the performance of liquid-filled gauges. By carefully selecting both the gauge material and the filling liquid, you can ensure optimal durability and accuracy tailored to your specific application.

Exploring Calibration Standards for Liquid Filled Gauges: Ensuring Precision in Measurement

When selecting the right liquid filled gauges, it is crucial to understand the calibration standards that underpin their reliability. Calibration serves as a foundation for precision in measurement, ensuring that the gauges perform accurately within their specified range. Recent developments in pressure measurement techniques highlight the importance of effective calibration: for instance, a new method utilizing cold atoms has emerged to measure pressure in ultrahigh vacuum conditions, demonstrating the continuous evolution in measurement technology.

One essential tip for choosing liquid filled gauges is to consider their calibration requirements. Understanding the various calibration methods available can greatly influence the accuracy and reliability of your measurements. For example, integrating secondary measurement standards can enhance calibration processes for dynamic pressure sensors, bridging the gap between static and dynamic measurements.

Additionally, always ensure that the gauges you select adhere to established calibration protocols. These protocols are not only vital for maintaining safety but also play a significant role in enhancing measurement fidelity. Recent studies have illustrated the effectiveness of various calibration techniques across different applications, underscoring that a rigorous approach to calibration can substantially improve operational efficiency.

5 Essential Tips for Choosing the Right Liquid Filled Gauges - Exploring Calibration Standards for Liquid Filled Gauges: Ensuring Precision in Measurement

| Dimension | Description | Importance |

|---|---|---|

| Fluid Type | The type of liquid used in the gauge (e.g., glycerin, silicone). | Affects the gauge's performance and longevity. |

| Case Material | Material used for the gauge casing (e.g., stainless steel, plastic). | Ensures durability and resistance to environmental factors. |

| Calibration Standard | Standards indicating the accuracy of the gauge (e.g., ASME, ISO). | Ensures reliability and compliance in measurements. |

| Pressure Range | The operational pressure range the gauge can measure. | Critical for selecting appropriate gauges for specific applications. |

| Connection Type | Type of fitting used to connect the gauge to the system (e.g., NPT, flange). | Ensures compatibility with existing equipment. |

Cost-Benefit Analysis of Liquid Filled Gauges: Balancing Quality and Affordability

When selecting liquid filled gauges, a cost-benefit analysis is crucial to ensure you’re making a sound investment. According to a report from the Pressure Gauge Manufacturers Association, the global market for liquid filled gauges is expected to grow at a CAGR of 4.2% from 2021 to 2026. This growth is driven by increasing demand for high-quality gauges in diverse applications, such as in the oil and gas sector, where reliability is critical.

Investing in liquid filled gauges often means weighing their initial higher cost against their enhanced performance and longevity. For instance, a study published by Gauge Technologies indicated that liquid filled gauges can reduce maintenance costs by up to 30% over five years compared to standard gauges due to their superior vibration damping and shock resistance. While the upfront investment may be greater, the long-term savings on replacements and repairs, alongside improved safety and accuracy, provide a compelling case for their adoption in industrial settings.

Related Posts

-

The Ultimate Guide to Choosing the Perfect Digital Manometer for Your Needs

-

The Future of Test Instruments in Industry Innovation

-

10 Essential Tips for Choosing the Right Test Instruments for Your Business

-

5 Reasons Why Precision Devices Are Essential for Modern Manufacturing Success

-

10 Essential Tips for Choosing the Best Digital Pressure Gauges in Your Industry

-

Unlocking the Advantages of Advanced Test Instruments for Quality Assurance

Contact

3295 Cobb International Blvd.

Kennesaw, GA 30152

800-367-1377

sale@patiostools.com

Info

© 2023 - Marsh Instruments